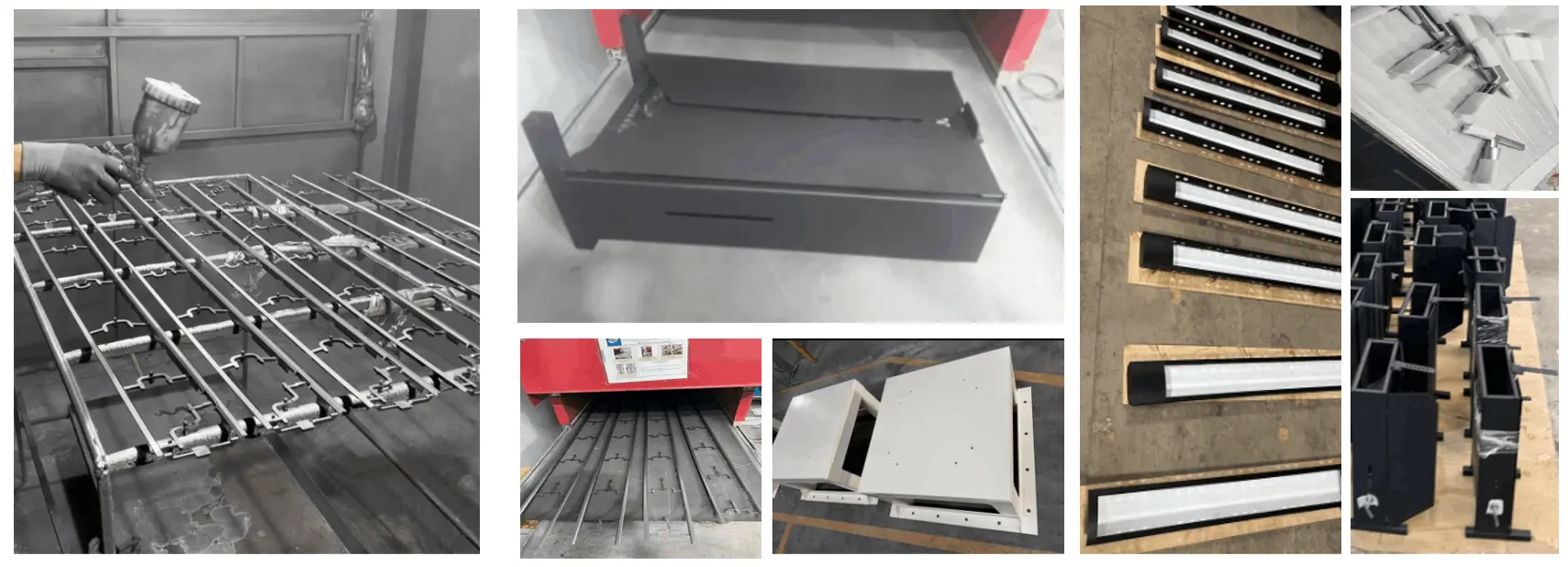

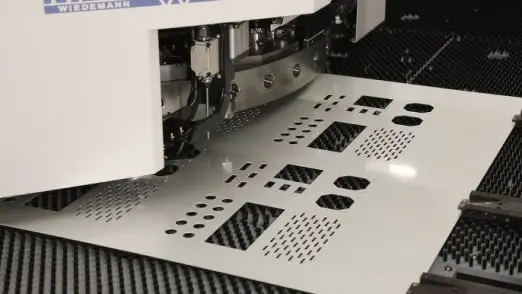

WET PAINT OR SPRAY SOLUTION.

Applying water or solvent-based paints to metal or plastic parts along with low to mid-temperature forced air drying is well within our capabilities.

An open-ended wet paint spray booth and conveyor oven are also available, for high and low volume.

The parts that can be painted using these processes can have the following maximum sizes:

Height: 50cm / Width: 50cm” /Length: 600cm

Oven Dimensions (30 meter length).